Ginger processing

Practical Action

Quality assurance of dried ginger

Quality of the dried ginger is assessed by the appearance of the final product (colour, lack of

mould or aflatoxin) and the aroma and flavour.

These qualities are influenced by a combination of pre- and post-harvest factors:

The most important factor is the cultivar of ginger used as this determines the flavour,

aroma, pungency and levels of essential oil and fibre.

The stage or maturity of the rhizome at harvest determines its suitability for end use.

Rhizomes that are 8-9 months old produce the best quality dried ginger as they have a

good combination of aroma and pungency and not too much fibre.

After harvest the rhizomes should be handled with care to prevent injury. They should be

washed immediately after harvest to ensure a pale colour. The wet rhizomes should not

be allowed to lie in heaps for too long as they will begin to ferment.

Care should be taken when removing the outer cork skin. It is essential to remove the

skin to reduce the fibre content, but if the peeling is too thick, it may reduce the content

of volatile oil which is contained near the surface of the rhizome.

During drying the rhizomes should lose about 60-70% of their weight and achieve a final

moisture content of 7-12%. Care should be taken to prevent the growth of mould during

drying.

The use of a mechanical drier produces a higher quality, cleaner product. The drying

conditions can be carefully controlled and monitored and the time taken to dry is

considerably reduced.

After harvest, the cleaning, peeling and drying processes should be carried out as quickly

as possible to prevent the growth of bacteria and mould and to prevent fermentation. If

the drying process takes too long there is a risk of the ginger becoming infected by

aflatoxin or other fungus.

Dried ginger should be stored in a dry place to prevent the growth of mould. Storage for

a long time results in the loss of flavour and pungency.

Grading

Quality specifications are imposed by the importing country and refer to the cleanliness

specifications of the ginger rather than the quality. It is important to meet the minimum

standards or the ginger will be rejected by the importers.

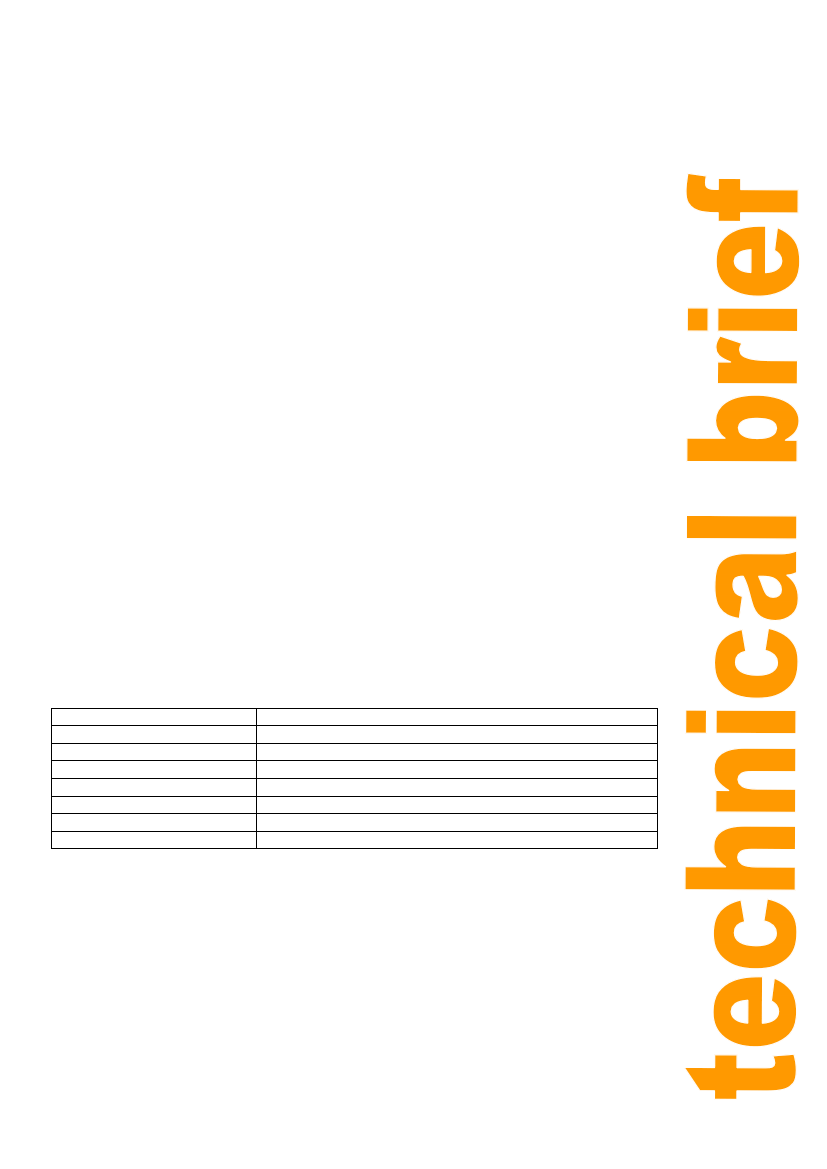

There are several forms of dried rhizome, which are described below:

Type

Peeled, scraped, uncoated

Rough scraped

Unpeeled, coated

Black ginger

Bleached

Splits and slices

Ratoons

Description

Whole rhizome with the corky skin removed

Whole rhizome with the skin partially removed

Whole rhizome with the skin intact

Whole rhizome scalded before being scraped and dried

Whole rhizome treated with lime of diluted sulphuric acid

Unpeeled rhizomes, split or sliced

Second growth rhizomes, small, dark and very fibrous

Grinding

Grinding can be a method of adding value to a product. However, it is not advisable to grind

spices as they are more vulnerable to spoilage after grinding. The flavour and aroma compounds

are not stable and will quickly disappear from ground products. The storage life of ground spices

is much less than for the whole spices. It is very difficult for the consumer to judge the quality

of a ground spice. It is also very easy for unscrupulous processors to contaminate the ground

spice by adding other material. Therefore most consumers, from wholesalers to individual

customers, prefer to buy whole spices.

Dried ginger is usually exported whole and ground in the country of import.

3